Burrs Factory

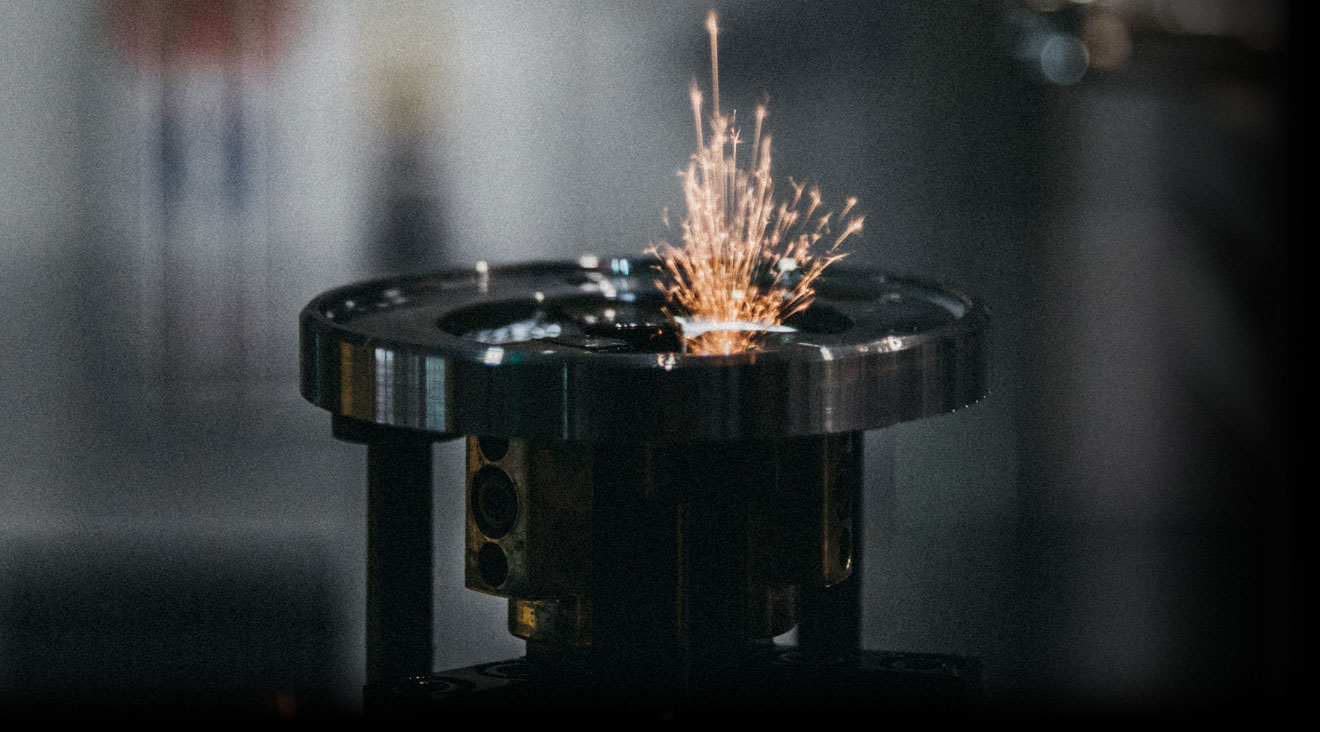

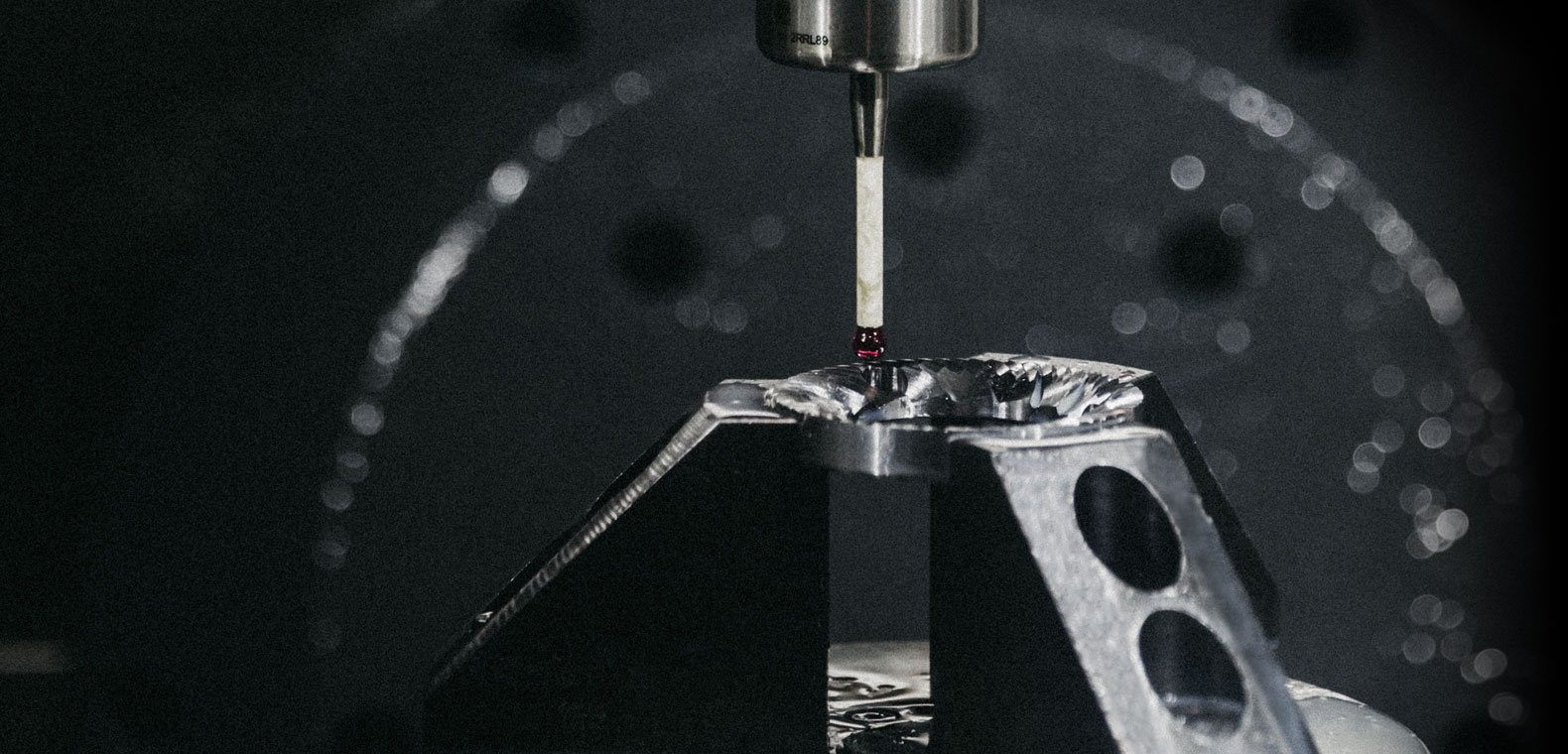

For the production of our burrs, we work with state-of-the-art numerical control machines, robotics, and quality control equipment.

100% In-House Manufacturing

The in-house production of burrs streamlines each stage of the manufacturing process, achieving precise control over components and production phases, while also eliminating material transportation and reducing environmental impact.

At COMPAK, we remain committed to sustainability.

Traceability

Traceability in burr manufacturing ensures quality and precision, guaranteeing uniform grinding for perfect coffee extraction.

It allows control over each stage of the process, ensuring durability and high performance in the grinders.

Designed to be versatile

The geometry of our burrs can be easily adjusted to different brewing methods and grind settings.

Whether using a coarse grind for your French press or a fine grind for your Espresso machine, our burrs provide stable consistency over time.

Quality control

Manufactured with meticulous attention to detail, our burrs are precision-designed and backed by years of experience.

Each unit undergoes rigorous testing to meet our exacting standards, ensuring durability and the highest quality.

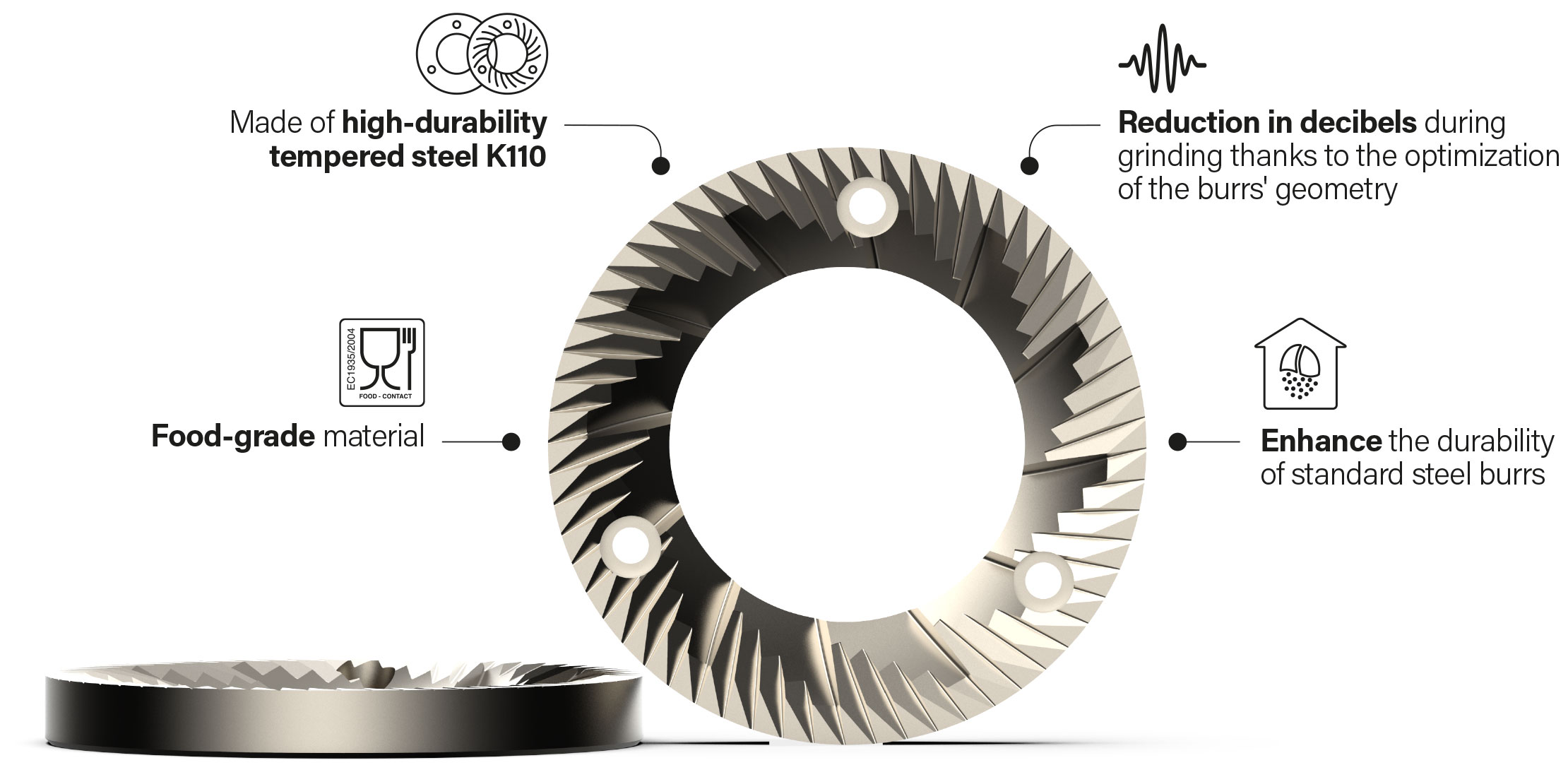

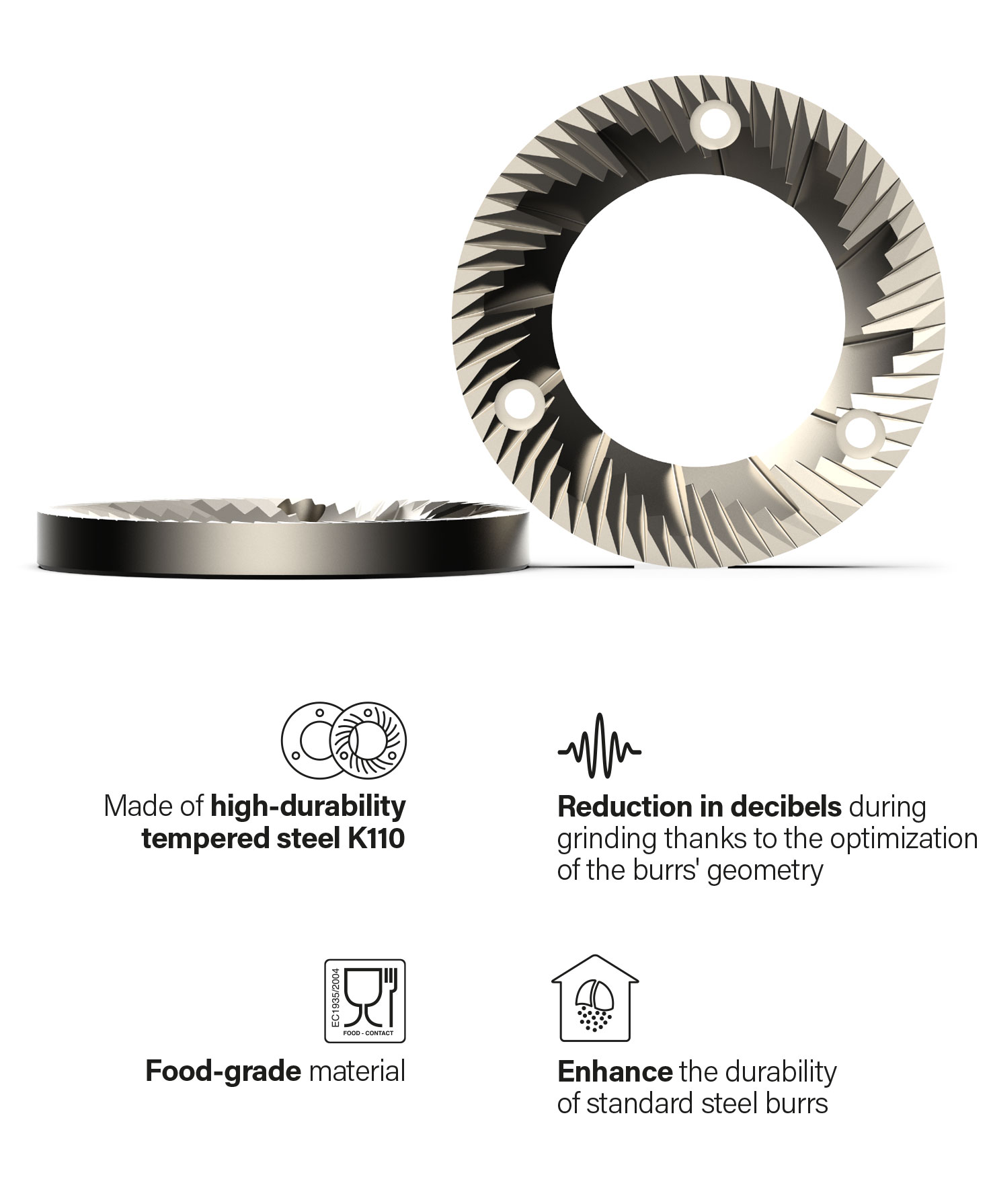

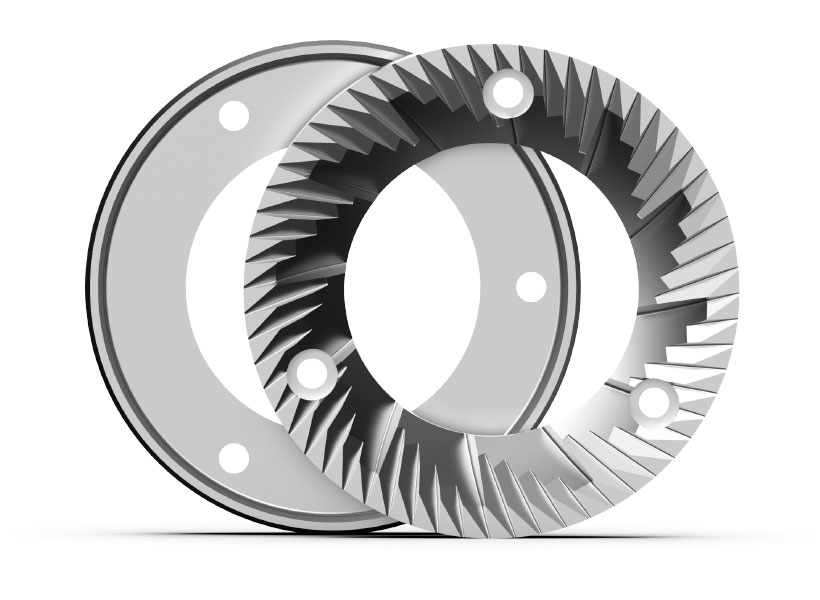

Standard Burrs

Tempered K110 steel

Flat Ø 83 mm

Durability

800 kg

Compatible grinders

F8 / Bolt 83 / E8 OD / R8

Flat Ø 64 mm

Durability

600 kg

Compatible grinders

Bolt 64 / E6 OD / K6

Flat Ø 58 mm

Durability

400 kg

Compatible grinders

i3 Pro / i3 Touch

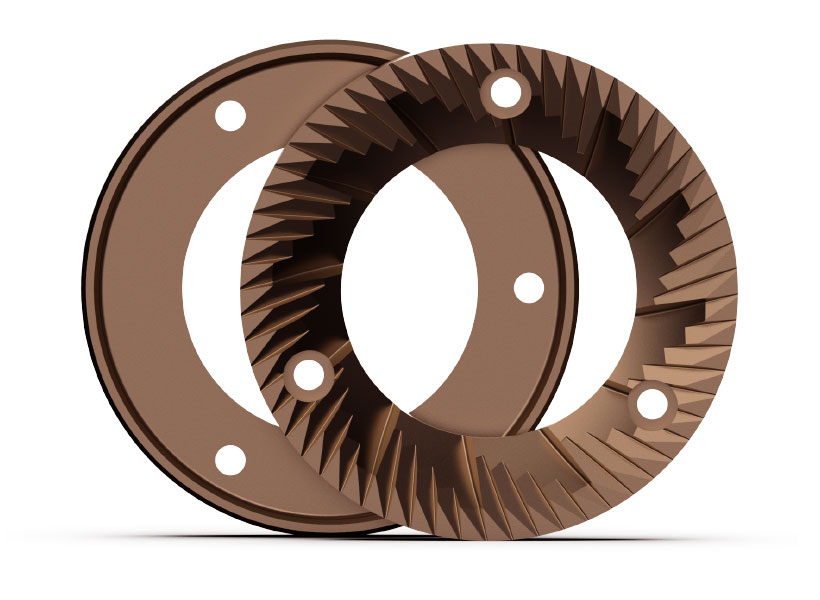

Long-lasting Red Speed Burrs

Titanium Nitride, Aluminum and Carbon

Flat Ø 83 mm

Durability

5.000 kg

Compatible grinders

F8 / Bolt 83 / E8 OD / R8

Flat Ø 64 mm

Durability

2.250 kg

Compatible grinders

Bolt 64 / E6 OD / K6

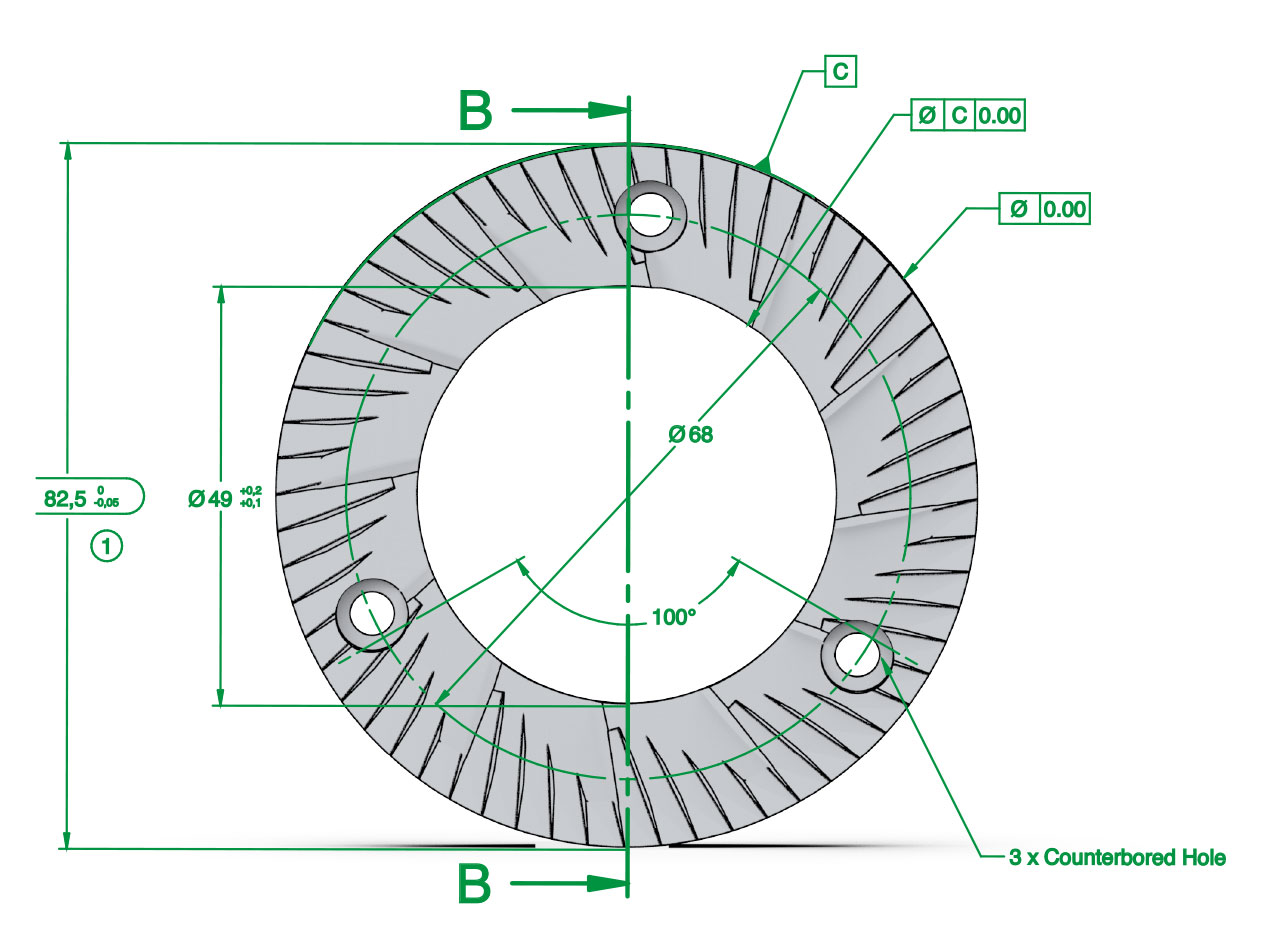

Conical Ø 68 mm

Durability

8.000 kg

Compatible grinders

F10 Master / E10 Master